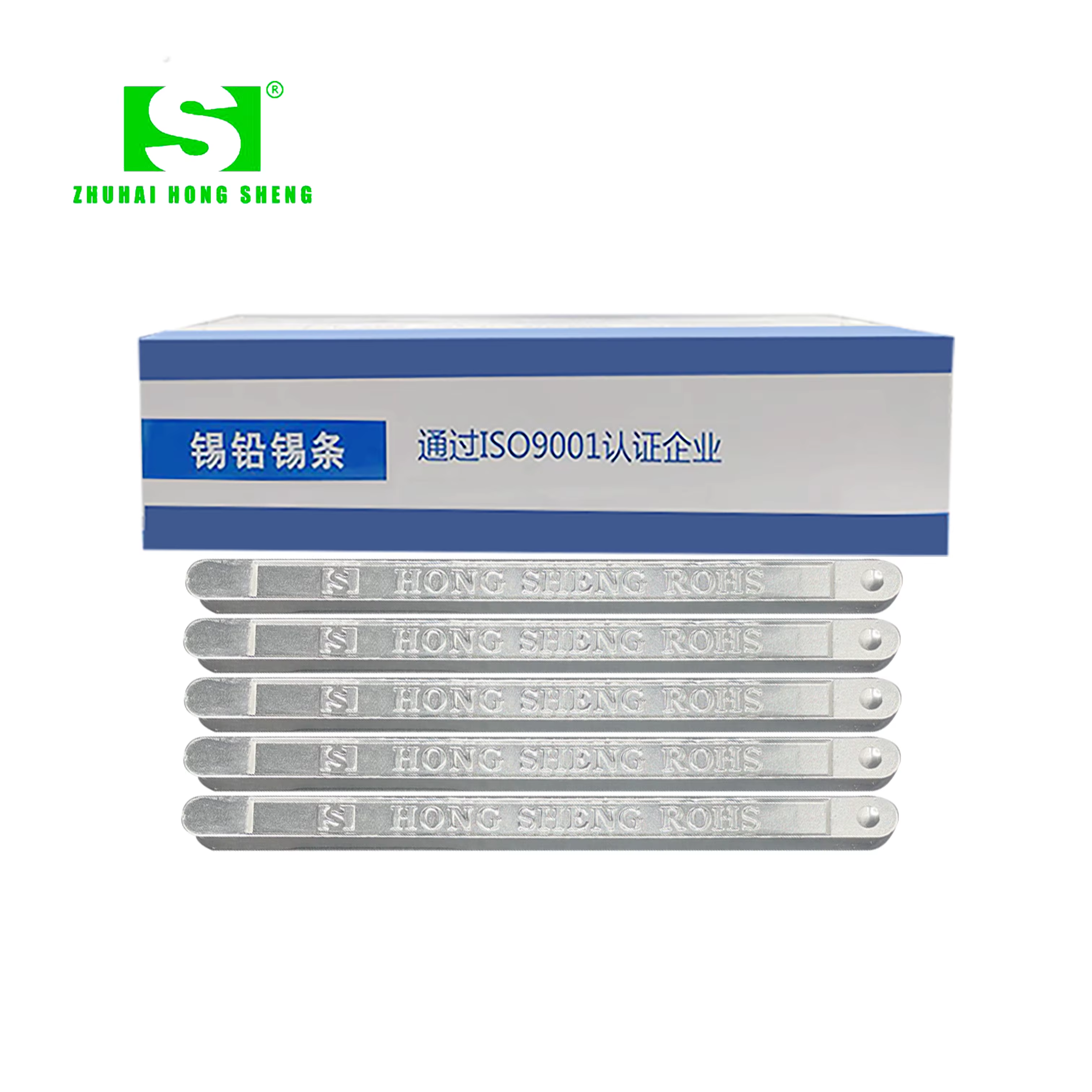

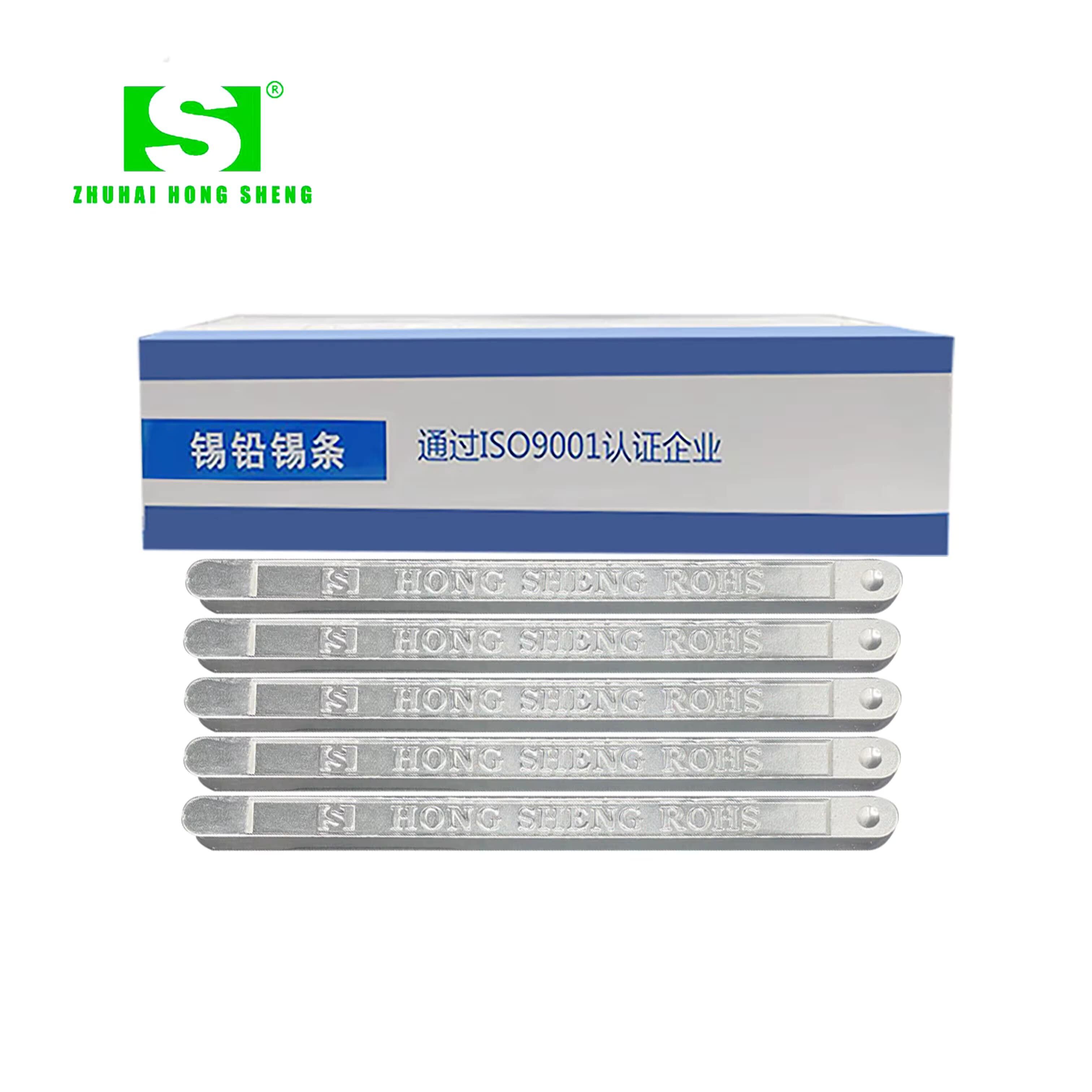

Top 5 Iraq Solder Bar Manufacturers - High Quality and Performance

Solder bars is essential elements the manufacturing of electronic devices. The Hong Sheng entire process of involves the use of heat and a metal alloy to be noted on two metal components. Because of higher need electronic devices in Iraq, soldering has turned into a prominent skill in the United states.

Iraq has a number of the best solder bar manufacturers that produce high-quality and performance-oriented products. We are going to be discussing the most notable 5 solder bar manufacturers in Iraq and the advantages of using their products.

Advantages of Using Solder Bars

The use of solder bars in electronic production means that the bones between equipment is conductive and solid. Soldering helps to make sure that electronic devices work optimally with minimal risks of injury to the component section. With proper soldering, electrical connections are secured and safeguarded from outside facets which will result harm, such as dampness and real shocks.

Innovation and Safety Considerations

The top solder bars manufacturers in Iraq prioritize safety and quality inside their production processes. The Solder Tools adopt cutting-edge technologies that enable soldering and dependable safe. Such innovations consist of lead-free safe solder bars for the surroundings and employees throughout use and manufacturing.

Service Quality and Application

The quality of service provided by Iraqi solder bar providers is top-notch, and the solder paste offer solutions which meet with the specific requirements of their clients. They provide unique advice on how best to use their products and protect optimal performance.

Practical and Safe Use

Concerning practical use, soldering bars must be retained in cool and dry conditions to prevent contamination. Before use, the solder bar needs to be cleaned to make certain good wetting adhesion during application. Clean surfaces is critical for appropriate soldering, while they enable maximum fusion and movement associated with the metal equipment.

EN

EN

AR

AR

FR

FR

DE

DE

RU

RU

VI

VI

TH

TH

TR

TR

MS

MS

BE

BE