Introduction

Introduction

Hong Sheng

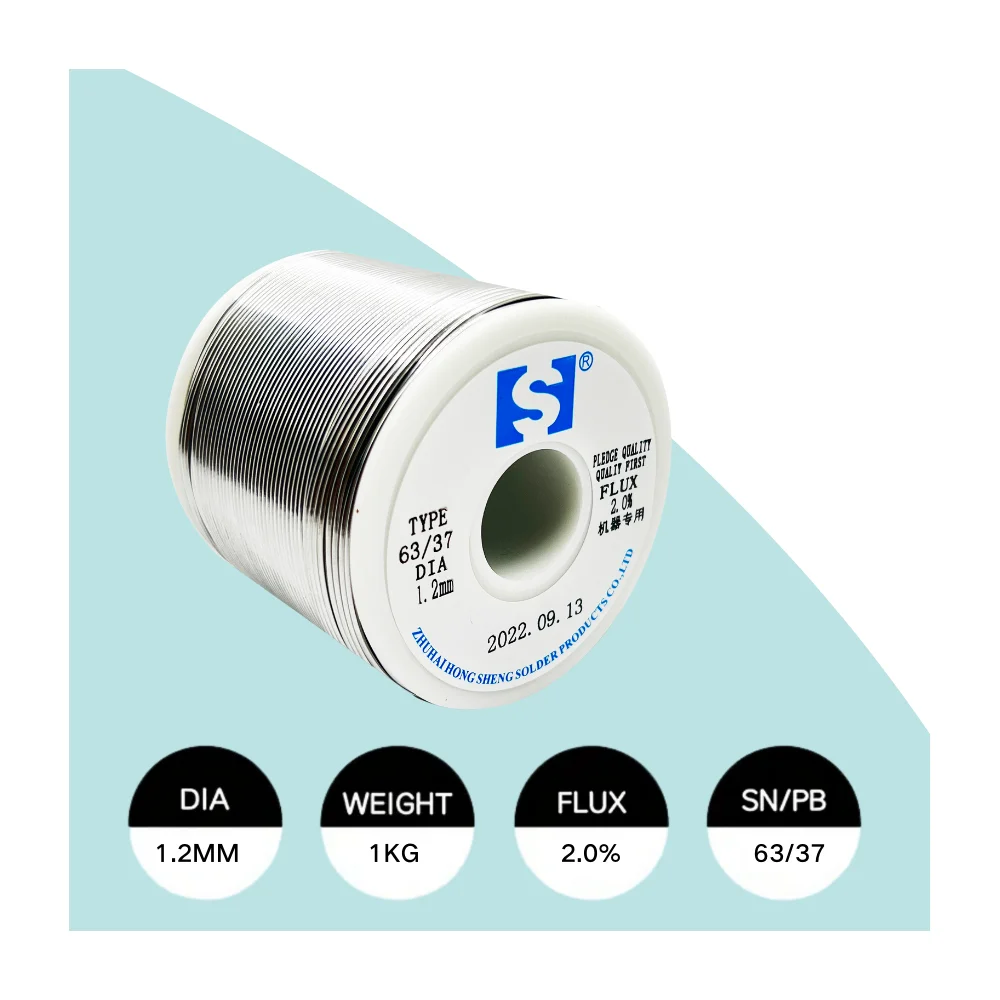

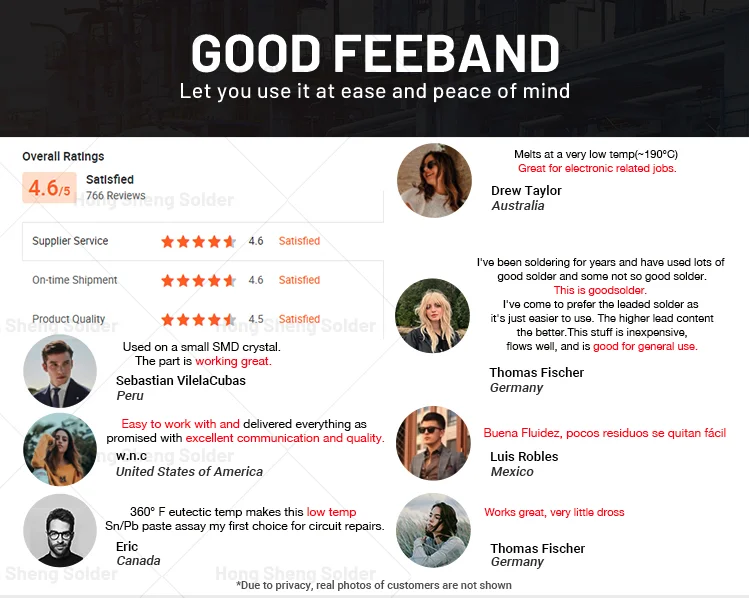

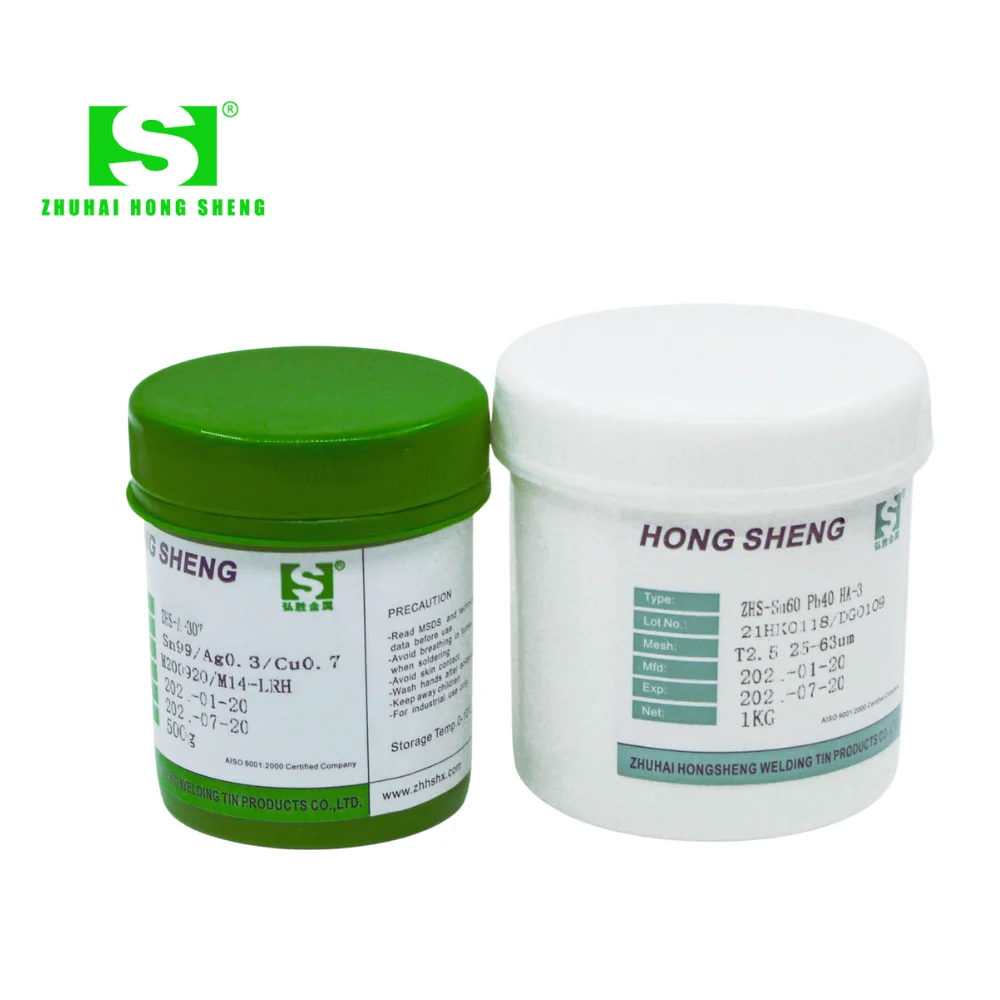

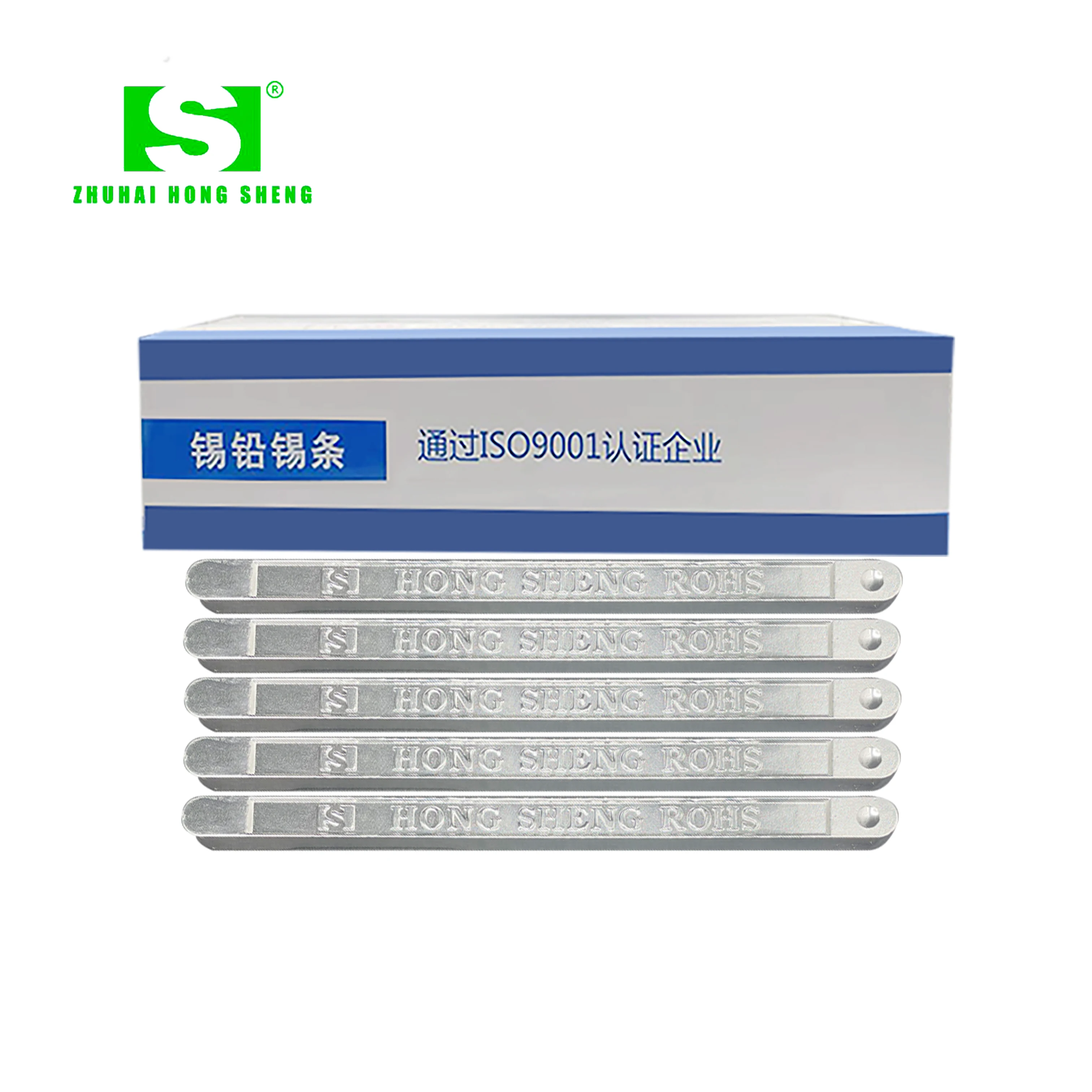

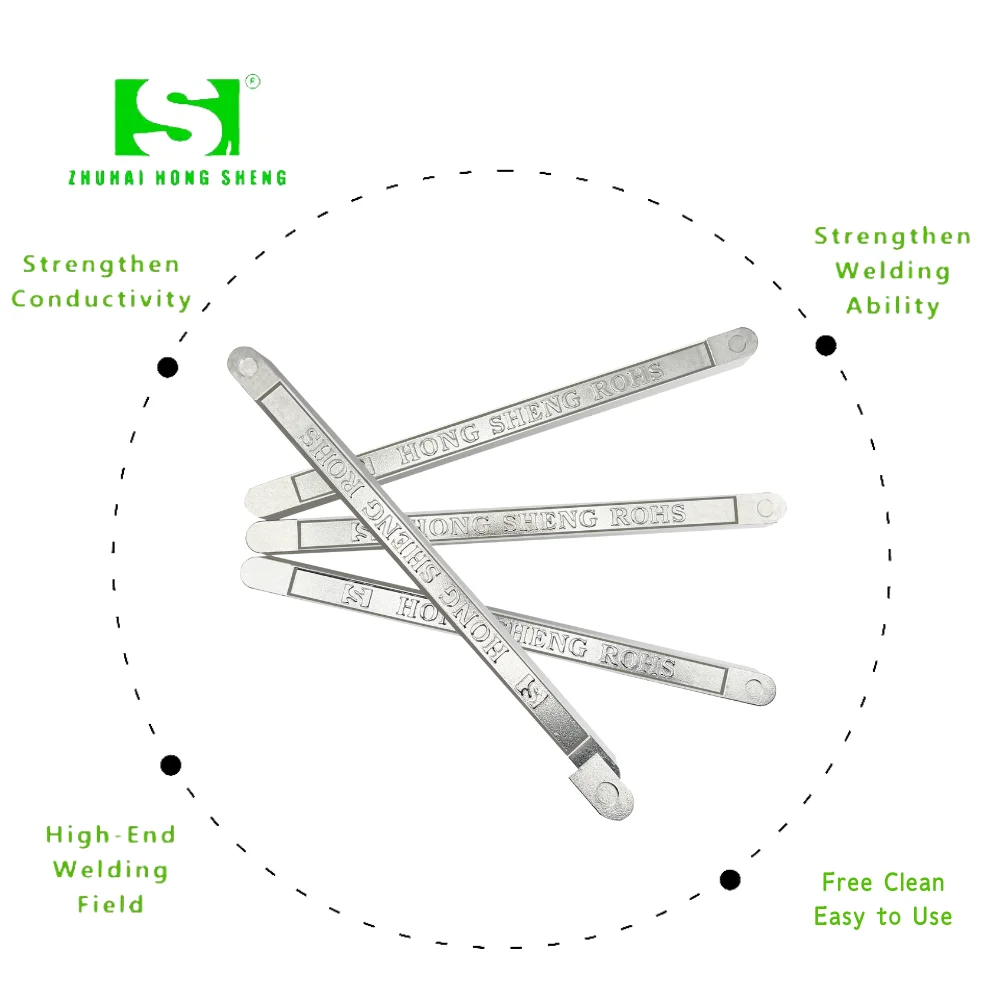

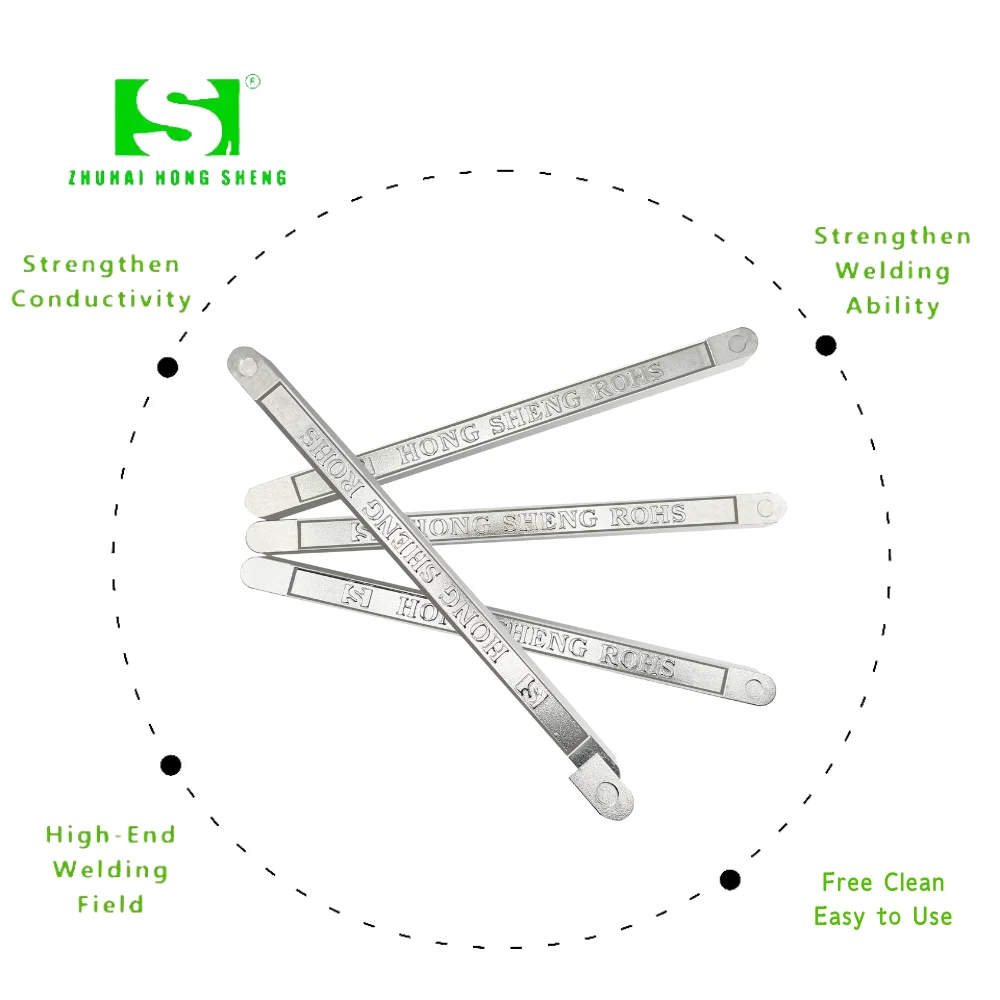

Tin Solder High Purity Welding Wire can be a product is great widely used for soldering and welding. It's a welding is top-notch that was created to supply great workability and durability is certainly lasting. This welding wire has recently gained popularity since it is the clear answer is perfect all your soldering needs. Made from top-quality materials, this soldering cable provides conductivity that is excellent strong bonding capacity that ensures a neat and weld is safe.

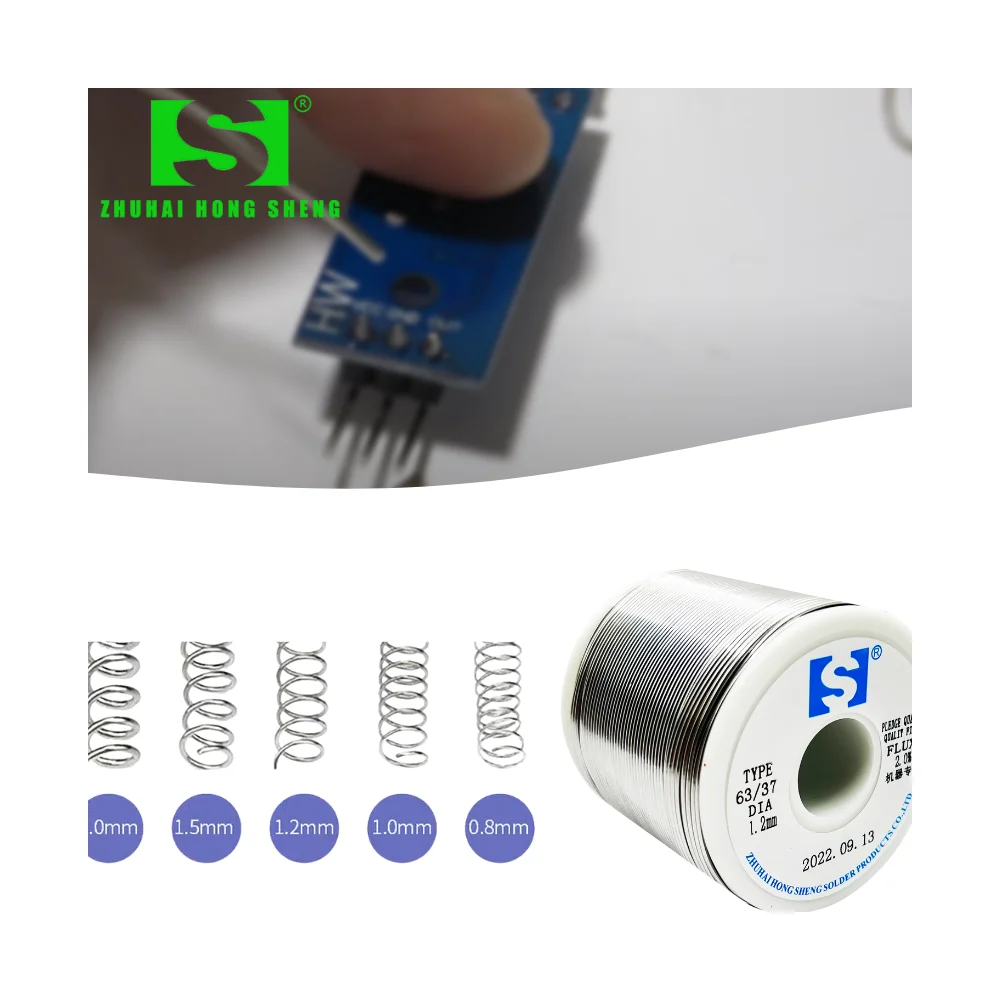

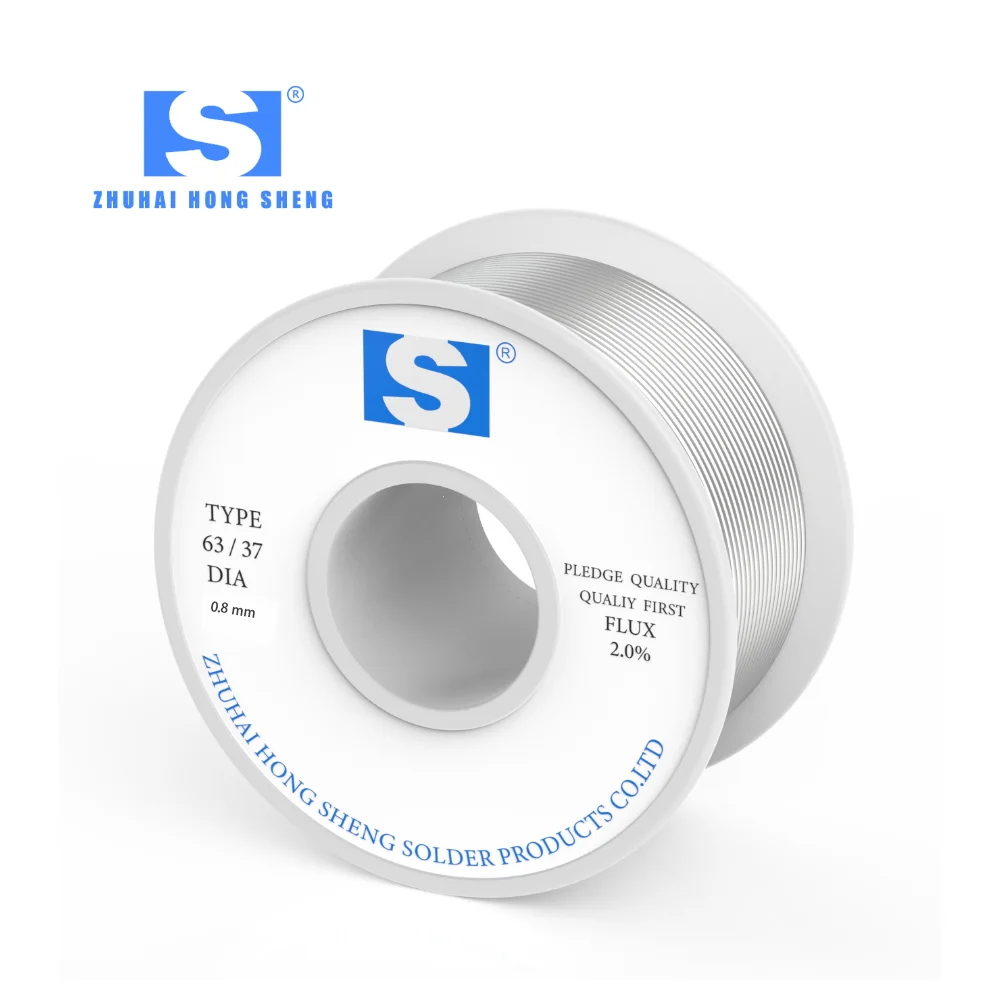

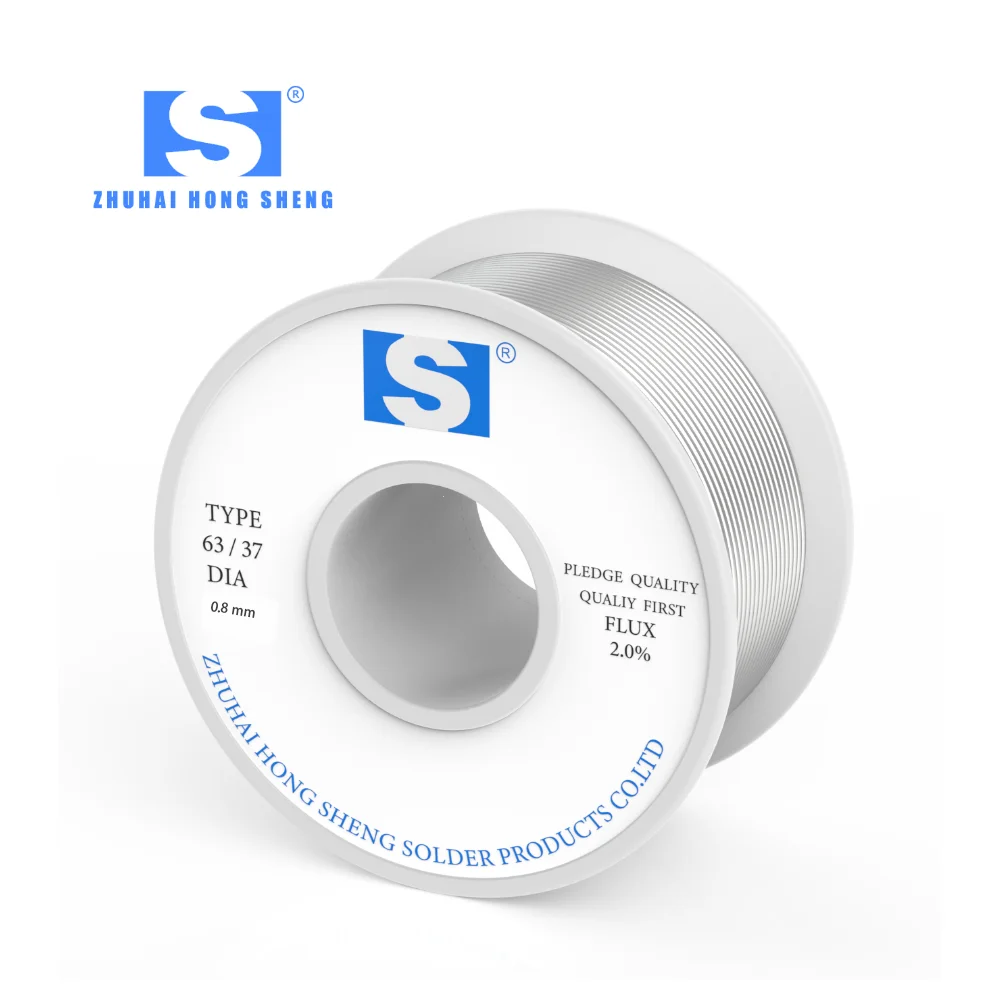

The wire’s conductivity this is certainly superb is high transmitting electric signals and energy that makes it suitable for use within medical, automotive, aerospace, electronics, along with other applications. Hong Sheng Tin Solder High Purity Welding Wire features a diameter of 0.8mm, providing an amount that is significant of and ease of good use. The cable was created to provide high-performance scaling that is technical that will be ideal for high-temperature applications.

Hong Sheng Tin Solder High Purity Welding Wire offers soldering that is top-notch, without being impacted by environmental facets. The wire is resistant to oxidation, corrosion, and rust, ensuring your weld remains strong over time. This method is established purity that is utilizing is high, exceeding international item standards.

Another feature is certainly exciting of Hong Sheng Tin Solder High Purity Welding Wire is its simple melting properties. It melts quickly and firmly, that makes it a breeze to utilize. In addition, it doesn't create smoke or smells, rendering it ideal for indoor soldering applications.

The versatile and easy features provided in this welding wire ensure it is a choice is certainly novice that perfect expert welders alike. Utilizing the quality features in place, it offers a fantastic solution is economical fulfilling your soldering needs into the run is long.

The Hong Sheng Tin Solder High Purity Welding Wire is eco-friendly, free of harmful substances that would be dangerous for individual life. Its melting is low point that soldering isn't complicated, which reduces the possibility of injury to hardware is intricate.

Brand |

HongSheng |

Type |

TIN wire |

Material |

63/37 ; 60/40 (Lead Solder Wire ) |

Scope Of Application |

Electric power industry & lighting industry |

Welding Type |

Fusion Welding Brazing Pressure Welding |

ODM/OEM |

YES |

Warranty |

3 years |

Spool Materials |

Rolling Wire |

Package |

Box |

Logo |

Accept Custom Logo |

Model |

Flux Content |

Diameter |

Weigth |

Melting Point |

Operating temperature |

Main Application |

||||

Sn99.3 Cu0.7 |

2.0% (Customized)

|

0.5-3.0mm (Customized) |

50g-1000g (Customized) |

227℃ |

370°±20° |

High-end Electronics

|

||||

Sn99.0 Cu0.7 Ag0.3 |

227° |

370°±20° |

||||||||

Sn63 Pb37 |

183℃ |

280°±20° |

For High precision PCB, like: Communication electronic, Micro electronic, aerospace industry, etc. |

|||||||

Sn60 Pb40 |

190℃ |

280°±20° |

||||||||

Sn55 Pb45 |

203℃ |

300°±20° |

||||||||

Sn50 Pb50 |

216℃ |

300°±20° |

Some normal electronics, like: home appliances, Electrical instrumentation, hardware, etc. |

|||||||

Sn45 Pb55 |

227℃ |

300°±20° |

||||||||

Sn40 Pb60 |

238℃ |

350°±20° |

Low requirement PCB, like: radiator, Lamp, cable connector, etc. |

|||||||

Sn35 Pb65 |

247℃ |

350°±20° |

||||||||

Sn30 Pb70 |

255℃ |

380°±20° |

||||||||

Sn25Pb75 |

266℃ |

400°±20° |

1: How about the terms of payment?

A: We accept T/T with 100% or 30% payment in advance; PayPal; Western Union.

2: What is your minimum order quantity (MOQ)?

A: Under FOB Price, it is usually 20kg at least.

3: What is your advantage of company and products?

A: We are one of the best factories in China, according to different welding materials, to provide customers with customized needs

4. What are your strengths?

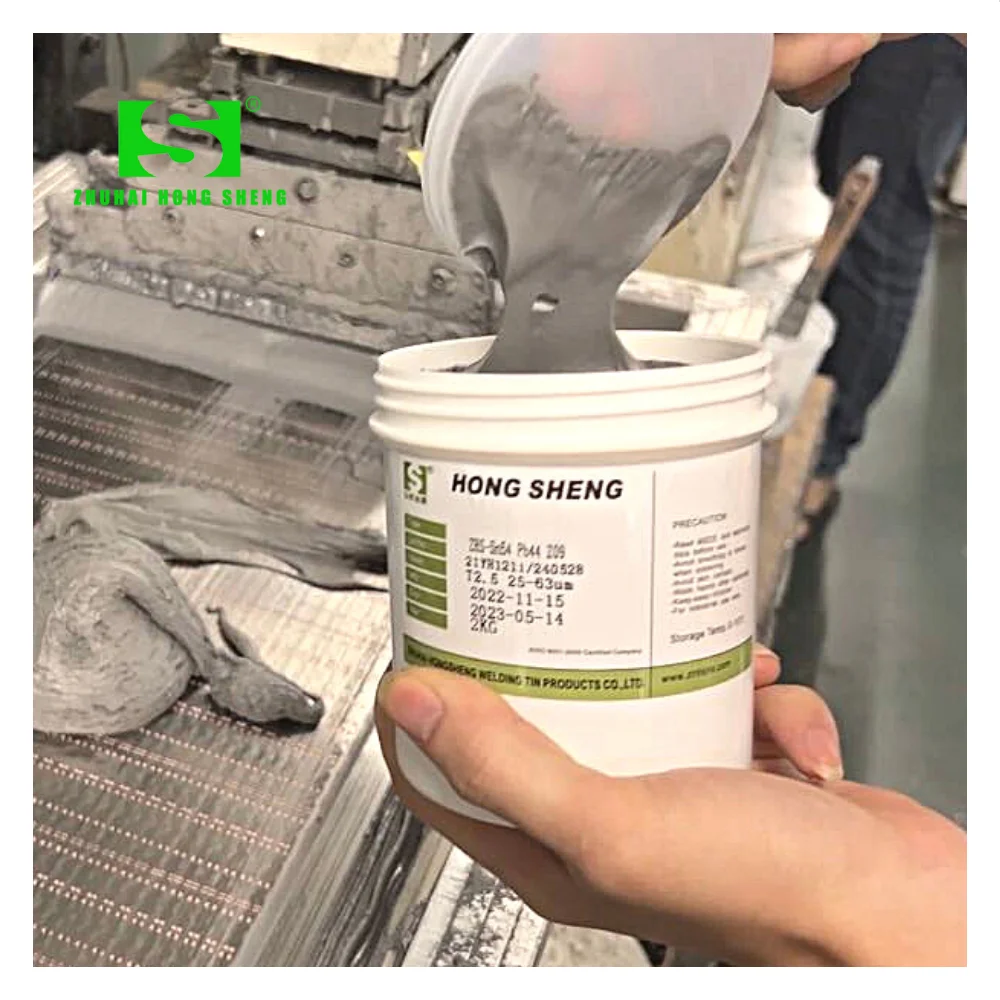

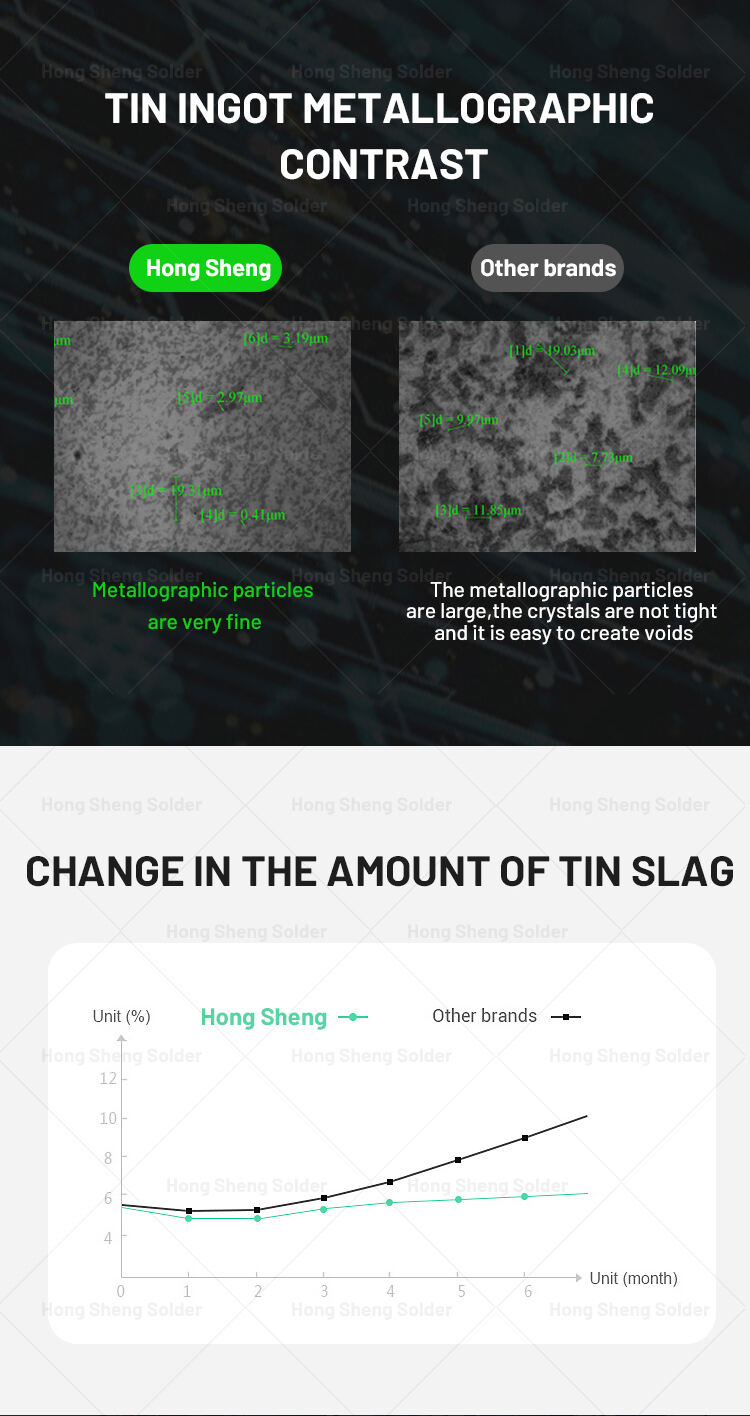

A: All our tin wires are made from refined tin ingots, and no recycled materials are used. The company has a mature technology and R&D team, and a unique flux formula. The tin wire has less rosin smoke and less rosin smell. At the same time, it has high stability during welding, and there will be no rosin splash, which ensures the safety of customers.

5. The difference between tin wire solid core and flux core

A: According to the manufacturer's requirements, the solid core has no flux, and the flux core has a layer of flux in the center of the tin wire.

6. Whether the weight of the tin wire is net weight and whether it supports customization

A: The weight of the tin wire is the net weight, that is, the weight excluding the rubber ring. Tin wire supports customization, i.e. tin wire diameter, flux content, the weight of each roll can be made according to customer requirements

EN

EN

AR

AR

FR

FR

DE

DE

RU

RU

VI

VI

TH

TH

TR

TR

MS

MS

BE

BE